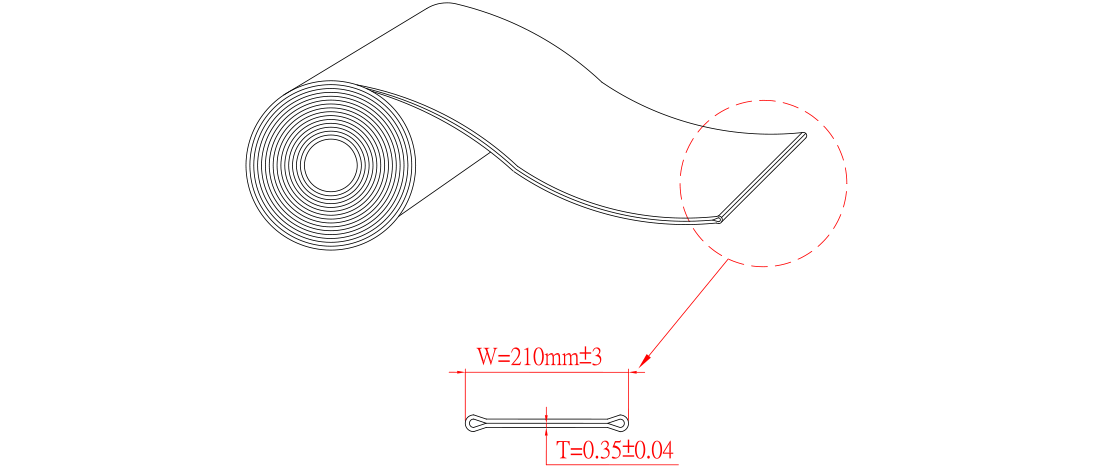

PVC Tubular Layflat and Roll

Bioteque IV bags are made by tubular films. These medical grade PVC based tubular films have proven to be the most reliable and cost effective material for IV bags. Due to its closed system, the interior of the tubular film is virtually free of particulate contamination, micro-organisms and pyrogens. A major advantage of the tubular film is the number of welds reduced to an absolute minimum thereby increasing the reliability of the final device. Another important advantage of tubular film is the cost saving effect ot reducing film waste during the production of bags. High frequency welding of the PVC based Bioteque IV bags offers a reduced risk of pinholes during the production of bags.

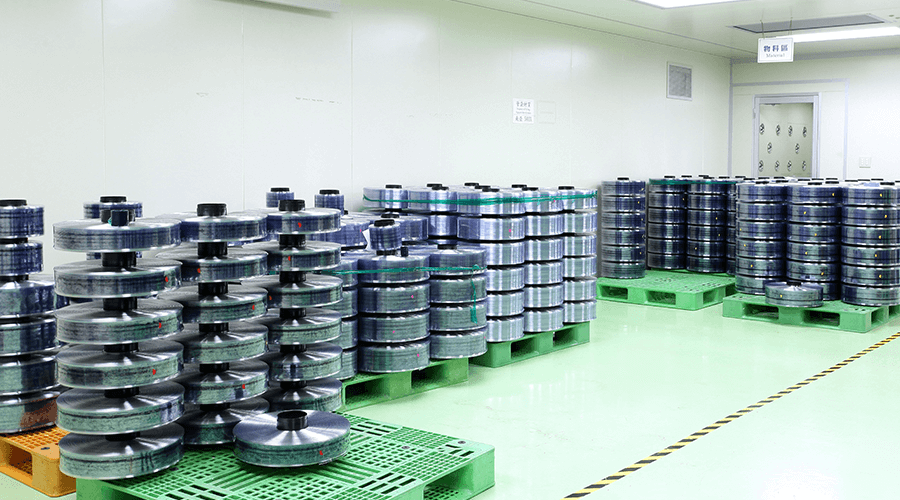

Bioteque has enough capacity for IV bag production, good production know-how and reliability of production line to guarantee safety of final product. We manufacture tubular film in a range of different specifications;and dimensions. (width min. 80 mm and max. 270 mm) with thickness of 0.32 mm, 0.35mm (per each sheet). Five production lines with an annual output of 68 million kilograms with fast delivery time.

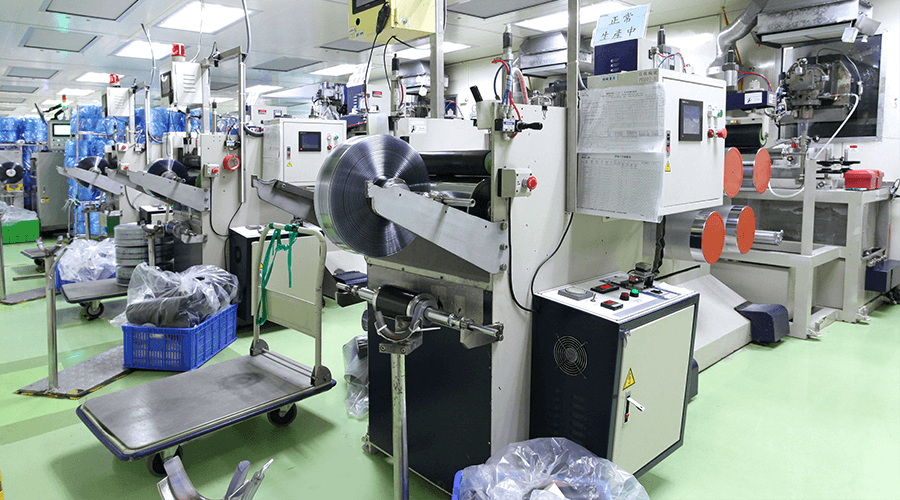

Layflat area:

- 5 PVC lines, including 5 fully automatic assembly machines.

- 3 stopper automatic assembly machines

Extrusion area:

- 5 PVC line

-11 Extruders

| Specification | Weight/Roll/KG | Roll (Meter) | Tolerance |

|---|---|---|---|

| 80MM*0.32 | 12.7 | 200M | W:±2mm T:±0.02mm |

| 80MM*0.35 | 13.88 | 200M | W:±2mm T:±0.02mm |

| 90MM*0.32 | 14.28 | 200M | W:±2mm T:±0.02mm |

| 90MM*0.35 | 15.62 | 200M | W:±2mm T:±0.02mm |

| 120MM*0.32 | 19.2 | 200M | W:±2mm T:±0.02mm |

| 127MM*0.32 | 20.2 | 200M | W:±2mm T:±0.02mm |

| 127MM*0.35 | 22 | 200M | W:±2mm T:±0.02mm |

| 180MM*0.35 | 18.74 | 120M | W:±2mm T:±0.02mm |

| 210M*0.35 | 21.88 | 120M | W:±2mm T:±0.02mm |

| 270MM*0.35 | 23.44 | 100M | W:±2mm T:±0.02mm |